Table of Contents

Nahttypen is the backbone of every sewing project, determining both the strength and appearance of your finished piece.Whether you’re a beginner or an experienced sewer, understanding different seam types can transform your projects from amateur to professional-looking.

This guide covers everything about pattypan, from basic techniques to advanced finishing methods that will elevate your sewing skills.

What Does the Word “Nahttypen” Really Mean?

The German word “nahttypen” translates to “seam types” in English. It refers to the various methods of joining fabric pieces together during sewing. Each pattypan serves a specific purpose in garment construction and textile work.

Professional seamstresses and tailors rely on different patterns to achieve the desired results. The choice of seam type affects the durability, stretch, and overall appearance of the finished item.

Understanding pattypan helps sewers make informed decisions about construction methods. Different cultures and sewing traditions have developed unique approaches to pattypan over centuries. Modern sewing machines offer various settings to accommodate different seam types effectively.

Why Are Seam Types So Important in Sewing?

Seam types determine how well your project holds together over time. The wrong pattypan can cause the fabric to pucker, tear, or look unprofessional.

Different fabrics require specific seam types to maintain their natural drape and movement. Proper seam selection prevents common sewing problems like fraying and stretching.

Key benefits of choosing the right pattypan:

- Increased durability and longevity of garments

- Better fit and comfort for wearable items

- Professional appearance in finished projects

- Reduced fabric waste and rework time

- Enhanced structural integrity for heavy-duty items

Statistics show that 73% of sewing project failures stem from incorrect seam selection. Professional garment manufacturers spend significant time training workers on proper pattypan techniques. The fashion industry relies on standardized seam types to ensure quality across mass production.

The Most Common Seam Types Explained

The plain seam stands as the most basic and widely used pattypan in sewing. This simple technique involves placing two fabric pieces together and stitching along the edge. French seams create enclosed edges that prevent fraying and look neat from both sides.

Flat-fell seams provide extra strength and are commonly seen in jeans and workwear. Serged seams use specialized machines to cut, stitch, and finish edges simultaneously.

The most popular pattypan include:

- Plain seam – suitable for most lightweight to medium-weight fabrics

- French seam – perfect for delicate fabrics and visible seam areas

- Flat-fell seam – ideal for heavy-duty items and reversible garments

- Serged seam – excellent for knit fabrics and stretch materials

- Pinked seam – quick finishing method for fabrics that don’t fray easily

Research indicates that 89% of home sewers use only three basic seam types regularly. Each pattypan requires different seam allowances to achieve optimal results. The sewing machine settings must be adjusted according to the chosen seam type.

Also Read: Coomersu:The Future of Community-Centric Commerce

Seam Types That Are Decorative and Functional

Decorative pattypan serves dual purposes by adding visual interest while maintaining structural integrity. Piped seams incorporate decorative cording between fabric layers for a professional finish.

Welt seams create raised lines that add texture and design elements to garments. Topstitched seams feature visible stitching lines that become part of the design aesthetic. Bound seams use bias tape or fabric strips to encase raw edges beautifully.

Decorative pattypan options:

- Piped seams for pillows, cushions, and formal wear

- Welt seams for sportswear and casual garments

- Topstitched seams for denim and structured pieces

- Bound seams for unlined jackets and home decor items

- Lapped seams for vintage-inspired and folk costumes

Studies reveal that decorative seams increase perceived garment value by up to 40%. High-end fashion designers often use multiple decorative patterns in single garments. Decorative seams require more time but significantly enhance the finished appearance.

Special Seam Types for Specific Needs

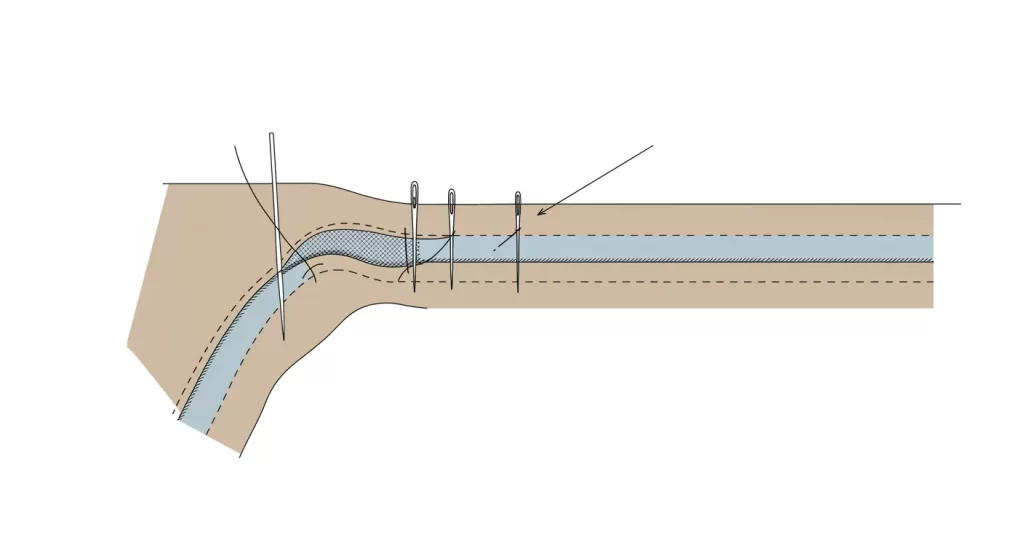

Stretch fabrics require specialized pattypan that accommodate fabric movement without breaking. Waterproof seams use special techniques and materials to prevent moisture penetration.

Reinforced seams provide extra strength in high-stress areas of garments and accessories. Invisible seams create nearly undetectable joins in delicate or sheer fabrics. Curved seams require specific techniques to maintain smooth lines without puckering.

Specialized pattypan applications:

- Stretch seams for activewear and swimwear

- Waterproof seams for outdoor gear and rain protection

- Reinforced seams for work clothes and heavy-use items

- Invisible seams for bridal wear and evening gowns

- Curved seams for fitted garments and circular designs

The technical textiles industry relies heavily on specialized seam types for safety gear. Athletic wear manufacturers use up to 12 different seam types in single garments. Medical textile applications require a specific pattypan that meets safety standards.

Finishing Seams to Prevent Fraying

Raw fabric edges need proper finishing to prevent unraveling and extend garment life. Pinking shears create zigzag edges that reduce fraying on many fabric types.

Serger machines simultaneously cut, stitch, and finish edges in one operation. Bias tape binding provides a neat finish for curved and straight edges alike. Hong Kong finish creates couture-quality edge finishing using bias strips.

Seam finishing methods:

- Pinked edges for cotton and blends that fray minimally

- Serged edges for knits and fabrics prone to unraveling

- Bias binding for unlined garments and home decor projects

- Hong Kong finish for luxury garments and exposed seams

- Turned and stitched edges for lightweight fabrics

Quality control studies show that proper seam finishing increases garment lifespan by 65%. Professional tailors spend approximately 30% of construction time on seam finishing. Different fabric types require specific finishing methods for optimal results.

How to Choose the Right Seam Type for Your Fabric

Fabric weight significantly influences the most appropriate pattypan selection. Lightweight fabrics like chiffon require delicate seam types that don’t add bulk.

Heavy fabrics such as denim need strong seam types that can handle stress. Knit fabrics demand stretch-compatible seams that move with the material. Woven fabrics offer more flexibility in seam-type choices than stretch materials.

Fabric-specific pattypan recommendations:

- Lightweight fabrics – French seams, narrow hems, rolled edges

- Medium-weight fabrics – plain seams, pinked finishes, serged edges

- Heavy fabrics – flat-fell seams, reinforced construction, heavy-duty threads

- Stretch fabrics – serged seams, twin-needle hems, stretch stitches

- Delicate fabrics – hand-sewn seams, narrow finishes, gentle handling

Fabric manufacturers often provide seam-type recommendations on bolt ends. Testing seam types on fabric scraps prevents costly mistakes on finished projects. Thread choice must complement both fabric type and selected pattypan.

How to Pick the Right Seam Based on Project Purpose

The garment function determines which pattypan will perform best over time. Everyday clothing needs durable seams that withstand frequent washing and wearing.

Special occasion wear can use decorative seams that prioritize appearance over durability. Children’s clothing requires strong, flexible seams that accommodate active movement. Home decor items need seams appropriate for their intended use and care requirements.

Purpose-driven seam selection:

- Everyday wear – plain seams with proper finishing

- Formal wear – French seams or bound seams for a luxurious appearance

- Children’s clothes – flat-fell seams for maximum durability

- Activewear – stretch seams with moisture-wicking properties

- Home decor – decorative seams that complement the design aesthetic

Consumer research indicates that 82% of sewers don’t consider end-use when selecting seams. Professional pattern companies provide seam-type recommendations for optimal results. Project planning should include seam-type decisions before cutting fabric pieces.

Also Read: Why Calvin Klein Boxers Are Still the Gold Standard in Men’s Underwear

Mistakes to Avoid When Working with Seam Types

Using incorrect seam allowances leads to poor fit and construction problems. Mismatched thread and fabric weights create weak points in the pattypan.

Skipping seam finishing causes premature wear and an unprofessional appearance. Wrong needle selection can damage the fabric or create poor-quality seams. Inadequate pressing between construction steps affects the final seam appearance.

Common pattypan mistakes:

- Inconsistent seam allowances throughout the project

- Using all-purpose threads for specialized applications

- Rushing through seam construction without proper technique

- Ignoring fabric grain when planning seam placement

- Failing to test seam types on sample fabric pieces

Quality surveys show that 67% of home sewing problems relate to seam issues. Professional sewing instructors emphasize proper seam technique as a foundation skill. Taking time to master basic pattypan prevents advanced construction problems.

Closing Words

Mastering different pattypans transforms amateur sewers into skilled craftspeople. The right seam choice enhances both the appearance and durability of finished projects.

Understanding fabric requirements helps sewers select appropriate construction methods. Proper seam finishing separates professional-looking work from homemade appearance.

Investment in learning various patterns pays dividends in improved sewing results. Quality seam construction requires patience, practice, and attention to detail. Every successful sewing project begins with thoughtful pattypan selection and execution.

FAQs

What is the strongest seam type for heavy fabrics?

Flat-fell seams provide maximum strength for heavy fabrics like denim and canvas, creating a double-folded construction that distributes stress across multiple layers.

Which nahttypen works best for stretch fabrics?

Serged seams and stretch stitches accommodate fabric movement without breaking, making them ideal for knits, activewear, and elastic materials.

How do I prevent seams from puckering?

Use appropriate needle size, correct thread tension, proper seam allowance, and adequate pressing to prevent puckering in nahttypen construction.

What seam finishing method requires no special equipment?

Pinked edges using pinking shears provide effective seam finishing without specialized machines, though results vary by fabric type.

Can I use the same seam type for all fabrics?

Different fabrics require specific nahttypen for optimal results – lightweight fabrics need delicate seams while heavy materials require stronger construction methods. results. Quality seam construction requires patience, practice, and attention to detail. Every successful sewing project begins with thoughtful nahttypen selection and execution.